Quality Inspection

We have unique facilities for material analysis and testing, metallurgical evaluation and corrosion testing.

We offer the following as a service to our customers

METALLOGRAPHY

Cutting, hot mounting, grinding, polishing, chemical & electrolytic etchingand engraving equipment used to complete metallographic preparations.

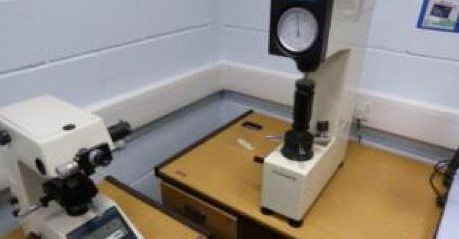

MICROSCOPY

Optical microscopes and scanning electron microscopy with EDX analysis.

HEAT TREATMENT FURNACE

To complete laboratory based heat treating activities useful in research.

CORROSION TESTING

Standard corrosion testing on ferrous and non-ferrous alloys according to internationally recognised standards e.g.ASTM(G48,G28,A262, etc), ISO or EFC.

MECHANICAL TESTING

Macro/micro hardness using Rockwell, Vickers and Brinell devices

STRESS CORROSION TESTING

Slow strain rate testing rig, 2L and 5L autoclave corrosion testing

QUALITY ASSURANCE SERVICES

Fully portable device for positive material identification by XRP technique LECO analyser for completing hydrogen analysis in weld wire.